Best practices to be followed for starting and sustaining a Tinkerers’ Lab

Tinkerers’ Labs provide an environment for innovation and practical skill development in young students. By following this blueprint, you can establish a thriving lab that inspires creativity and empowers the next generation of makers.

- When you plan to start a Tinkerers’ Lab, following to be considered:

-

- Space Design: Design your lab to promote collaboration and teamwork. Consider floor plans, furniture, electricity, and storage that cater to the activities of potential users. Ensure natural light and proper ventilation, while also providing air-conditioned areas for sensitive equipment. Mobile and adjustable computer workstations and multifunctional storage are recommended.

- Equipment and Tools: Tinkerers’ Labs focus on technology and engineering activities. Include automated machines, woodworking and metalworking tools, digital storage, and a library with inspiring how-to books and online repository of and project collections. We provide an inventory with price lists and suggested suppliers to help you begin. Download the full list here. Link to the equipment list.

- Plan for Power: Ensure ample electrical power and multiple outlets for your lab equipment, considering flexibility and adaptability.

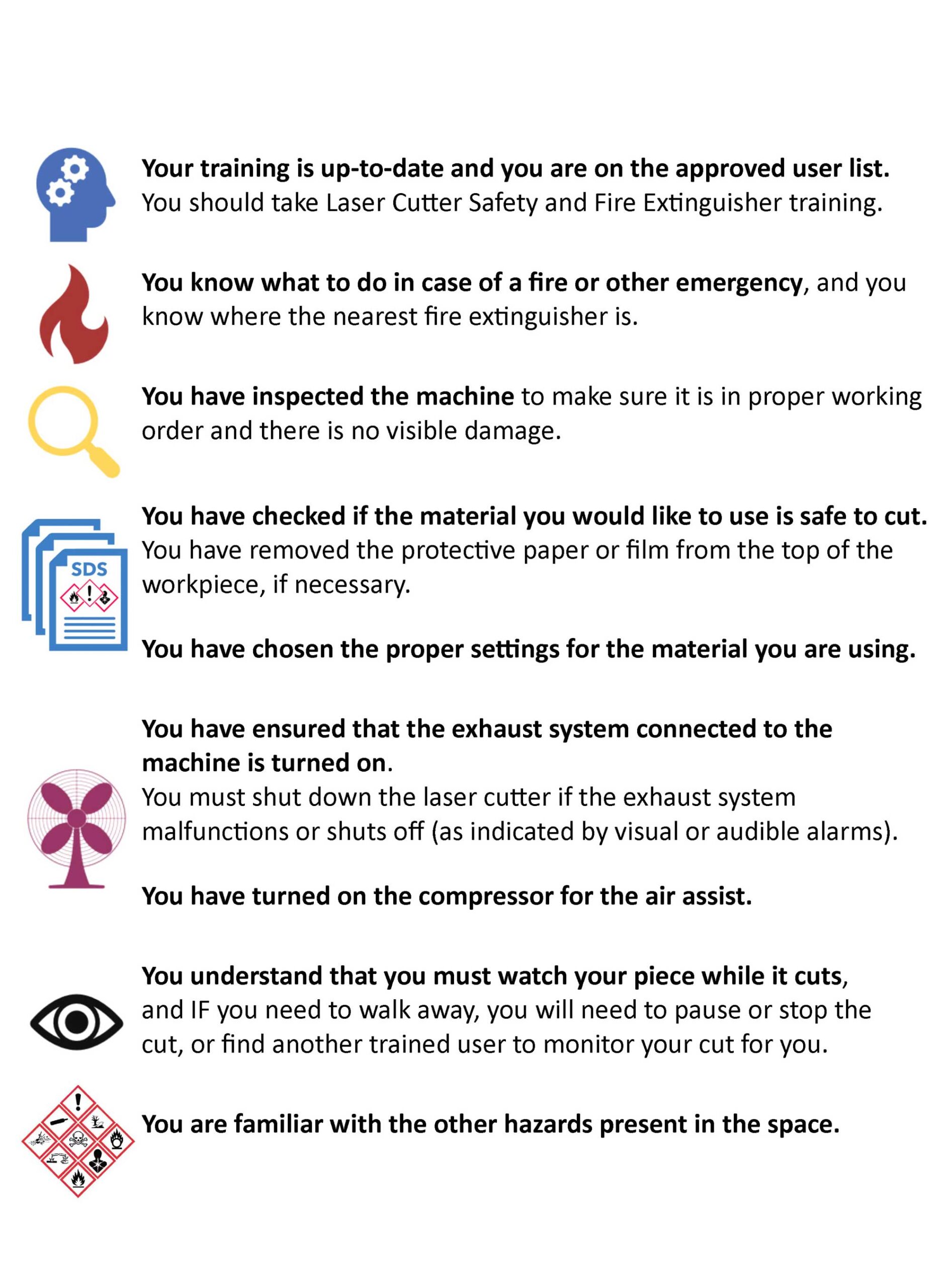

- Safety: Create a safe space for exploration with two exits and clear emergency paths. Regularly check fire safety measures and maintain first aid kits. Establish safety rules and ensure lab technicians supervise the use of power tools and large machines. For clarity, please download the lab safety manual from here. Link to Lab Safety Manual.

- Training and Documentation:

- Organize training workshops for equipment usage and offer periodic sessions for users.

- Two full-time trained technicians should be available to guide students.

- Maintain a lab entry log and automate processes to track equipment usage, user data, and project documentation(brief documentation template for reference) for analysis and evaluation. All this information will surely let us know if the lab is being run optimally. However, it is also important to understand how users perceive the setup. Hence it is important to run feedback surveys.

- Usage of machines requires additional training to be used, regardless of your experience with other similar machines that one has used earlier. While written training manuals are a way to train yourself to use the machines in the lab, it would help to attend a workshop and also watch training videos for more hands-on clarity. A few tips which are handy for training beginners are as follows:

- Have guided instruction for beginners in the form of training manuals and videos

- Allow users to work on their easy independent projects

- Combine both online and in-person training.

- In addition, the staff who conduct the instruction and

- Training should be approachable in order to cultivate a culture that embraces learning through experimentation and, at times, failure.

- Process Manual: Develop comprehensive manual documenting procedures and processes to ensure continuity as student teams change periodically. A sample of the operating manual can be found here. Link to a general operating manual for reference.

- Budgets: Consider capital expenditures for design, construction, equipment, and furniture. Allocate annual budgets for technician salaries, supplies, equipment maintenance, renovations, and honorariums for visiting educators. Repurposed and borrowed items can help maximize resources and foster a “maker mindset” of doing more with less. The blueprint estimates a budget of Rs. 50 lakhs to create and maintain a tinkerers’ lab for three years, with minor renovation costs. Plan for long-term sustainability beyond annual expenses.

- Outside mentors and Faculty Participation:

- Creating a database of industry mentors is highly beneficial for any Tinkerers’ Lab because such a database serves as a centralized repository for connecting students, tinkerers, faculty, and staff with professionals for efficient collaboration, customizing matchmaking based on specific fields, skills, industries, or areas of expertise, access to varied expertise, saving of time and resource when the need comes, sustainable networking, continuous engagement, help with strategic planning to align with the industry perspective, visibility and recognition of the lab, data-driven decisions by tracking the engagement and outcomes resulting from interactions with industry experts to understand which partnerships are most valuable and how to enhance the collaboration process.

- It is also important to have an experienced faculty lead with a similar passion for tinkering to get the most out of this kind of setup, specifically if the faculty lead has experience in an industry setup and hands-on experience with the latest technology along with this curiosity on par with students using the lab, then the faculty will be a valuable resource for students to take advantage of to hone their own skills and this trait would inspire them to explore and tinker more. This kind of faculty lead typically possesses specialized knowledge and skills related to the technologies, tools, and processes commonly found in the industry. Such faculty can provide guidance and instruction on how to engage in activities that are useful to the industry effectively.

- While having young faculty as mentors may not necessarily be the best approach, it is seen by experience that having young faculty as mentors usually infuses fresh perspective and enthusiasm, technology proficiency, relevance to student engagement, balanced with experience, strengthens the relationship between faculty and students, and fosters an environment where students feel secure that they can talk to faculty about certain needs and actually receive a response from faculty to their concerns.

- Event and Workshop Planning, Operations, and Continual improvements:

-

-

- Clear Outcomes and Benefits: Define event outcomes and participant benefits upfront for effective planning. Value addition is key, it could be any of the following forms: encompassing information, networking, and meaningful interactions with an added element of fun.

- Adhere to Policies: Follow institute policies meticulously to ensure seamless event operations. Acknowledge resource limitations during planning and find solutions to generate the maximum value out of existing resources.

- Prioritize Value Over Scale: Smaller, well-executed events can offer more participant value than larger ones. Prioritize stakeholder benefit over event size.

- Address Pitfalls: Unforeseen issues may arise during execution. Stay calm, consult your guides and PICs, and seek solutions rather than panicking. Avoid making impulsive decisions.

- Tracking Objectives: Set guidelines to track event objectives during execution. Establish communication channels with participants to gauge their opinions, and document them in video format(if possible) for future reference and to create a repository for marketing and outreach about the TL and its activities.

- Effective Feedback Collection: Design concise feedback forms for the team. Gather insights to incorporate them in future event planning and generate more value. Document valuable feedback for reference for future incoming TL teams.

-

- Kinds of workshops and events to be held:

Students from multidisciplinary areas usually have the hunger to learn about various aspects of a project. Organizing events and workshops would be a great opportunity for the students to develop new skills, expand knowledge and gain hands- on experience. To achieve all these, a Tinkerers’ Lab can organise workshops and events related to:

- Skill based workshops like 3D printing and Designing, coding and programming etc.

- Project based hackathons like theme specific challenges, cross disciplinary hackathons etc.

- Guest speaker talks to talk about industry culture

- Workshops on prototyping and iteration

- Design and innovation workshops

- Events like Tinkerers showcases and expos.

- Running and sustainability of the lab:

- Access 24/7: The lab should be accessible to students 24/7. The very reason that the lab is open 24/7 means it recognises that the users have diverse schedules particularly for those who want to use the lab to work on projects or tinker whenever inspiration strikes and whenever they find time. Hence it is imperative that the security measures are in place to ensure the safety of both the space and its members. In most of the labs, students who are trained well on using the machines are allowed to use the lab post working hours of the Institute. Ideally, there should be a lab technician who should work in 2 shifts.

- Students – the driving force: The beneficiaries of Tinkerers’ Labs are the students. Tinkerers’ Labs emphasise hands-on and experiential learning which aligns well with the preference of the students. Also students being the driving force encompasses a wide range of STEM students from diverse backgrounds coming together to run the lab which stimulates their personal motivation and initiative to value the space as a co-owner. This can drive inspiring students to seize opportunity. By making the student body owner of the space is also equivalent to honoring students’ resourcefulness and awareness of needs/ideas. This helps students to be active learners, participants in decision making, boosting their confidence and motivation. The core committee is generally inducted with the Student Manager(s) leading the team. This practice has worked well with the existing TLs.

- Diversity in participation: Besides gender, ethnicity, culture, generation, skills, socio economic diversities, one of the success factors of the Tinkerers’ Lab is having students/community members from inter disciplinary use the lab. Having said that, simply making the makerspace interdisciplinary is not enough. A diverse makerspace should

- Target both experienced and inexperienced users.

- Address the diverse usage requirements. It should be a place where the community should freely be able to prototype, meet up with people, and get your creative juices going.

- Include group of users, staff and administrators should also consider providing a variety of low-tech tools and supplies including prototyping and material-based tools instead of only supplying high-tech equipment.

- Address various learning styles of the participants because there will be students/members with different learning style compatible – Egs: hands-on project based learning, following general instructions for those who have no idea what to make, then moving on to project-based learning once the general instruction is completed. There could be others who would want to learn by being trained online and also in-house.

- Involvement of industry: An effort should be made by the TL student leadership, with the help of their PIC, alumni to bring in industry projects that students can work on. Students working on industry projects at TLs will be exposed to the professional reality of their field in the early stage of their professional life. Hence they develop transversal skills. Giving students the freedom and resources to be creative contributes in TLs produces graduates that are more employment-ready which makes it a good pool for industries to have.

- Community building: The Tinkerers Lab can be one of the components of building a community of Tinkerers on the campus/globally. It could strengthen the culture by enabling various kinds of Tinkerers to come together at a place, offering programs to connect members of various techno clubs etc. A community of alumni and anyone related to Makerspaces/Tinkerers Lab can be beneficial because this kind of model supports a culture of “problem-finding” vs solution-based thinking, taking constraints and problems and reframing them as opportunities upon which to build solutions from industry, research as well as day to day life perspectives.

A few steps to set up the community worth exercising is:

Understand the goals and objectives of creating this community.

Makerspaces should aim to offer community members

- Opportunities to collaborate (with other makers, researchers, faculty, industry partners)

- Access to shared resources – equipment, shops

- Use of private and shared spaces – labs, conference rooms, classrooms

- Clear and consistent policies

- Spaces that are safe, clean and have an efficient layout and operation

A few ideas to keep the community up and running:

- Identify a virtual space for communication for the community. For example – Whatsapp, Telegram, Linked-In.

- Identify a few moderators, drivers who will drive the community discussions

- Personalize the Experience

- Write Profile Stories

- Write Action Posts

- Create Member Prompts

- Run polls

- Write Compilation Posts

- Host Live Events (Online and In-Person).

- Encourage Interdisciplinary Team Projects: The Tinkerers Lab offers an ideal hub for interdisciplinary students to network and collaborate. Embracing this collaborative environment is paramount, as it offers unique educational experiences unmatched by external courses. Interdisciplinary projects fuel curiosity and form well-rounded teams, driving innovation. The potential for commercializing these innovations is increased by many folds, the main reason being diverse perspectives, another advantage is this practice would equip students with essential cross-disciplinary skills. This practice can inspire new career paths and expand opportunities for newer research areas for the students to Tinker/ explore. Moreover, it cultivates networking skills, pushing students out of their comfort zones to interact with peers from diverse fields and harness the benefits of networking.

- Importance of collecting regular Feedback: The Tinkerers Lab, a student-run interdisciplinary workspace, accommodates diverse Tinkerers and students. Leveraging this variety is crucial for the lab’s success. Gathering user feedback is vital for identifying challenges that the students face, initiating discussions, and implementing solutions and processes for improvement. This iterative process gradually enhances efficiency. Continuous growth and improvement involve creating concise feedback forms that engage users and gather essential information. Data collected, both quantitative and qualitative, should be readily analyzable. Additionally, focused group discussions offer valuable qualitative insights. Embrace creativity while thinking of ways to collect feedback. So the steps that are to be followed in order are: iterate through feedback, analyze, brainstorm solutions, execute, and repeat — fostering a closed-loop system for a smoother and more efficient lab operation and a valuable experience for its users.